Uèir Titanium

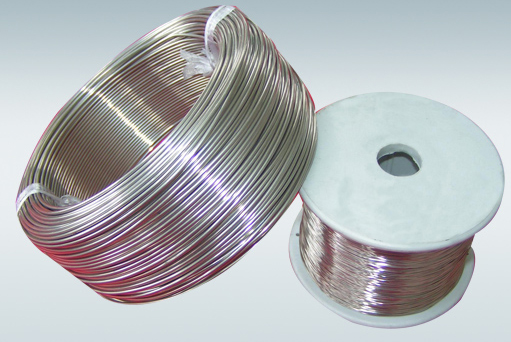

Uèir TitaniumTha an uèir titanium mar as trice air a chleachdadh airson tàthadh, frèamaichean, implantan lannsa, sgeadachadh, tàmh-àirneis crochte electroplating.Used ann a bhith a’ dèanamh pùdar titanium spherical.

Uèir cleachd am bàr titanium no leac Titanium a-steach don mholltair gus a phròiseasadh, mar thoradh air a’ bhuaidh tarraingidh, bidh am bàr titanium a’ deformachadh fo theòthachd àrd nuair a thèid e tro tholl a’ mholltair.Tha an crois-earrann air a lughdachadh, agus tha an fhaid air a mheudachadh.Bidh sìneadh ann an staid teasachaidh a ’cuideachadh le bhith a’ cuir às don cuideam a-staigh agus a ’leasachadh plastachd uèirichean titanium.Bidh e gu h-èifeachdach a’ leasachadh cruinneas an uèir titanium, agus an crìochnachadh uachdar, a dh’ fhaodas coileanadh coileanta nas fheàrr a choileanadh.

• Stuthan Titanium Wire: Ìre 1, Ìre 2, Ìre 5, Ìre 5, Ìre 7, Ìre 9, Ìre 11, Ìre 12, Ìre 16, Ìre23 msaa

• Foirmean Uèir: Spool ann an Coil, Gearr fad / dìreach

• Trast-thomhas:0.05mm-8.0mm

• Cùmhnantan:Fuasgladh air a chuir an cèill, ruith teth, sìneadh

• Surface:Piocadh geal, snasta soilleir, searbhag air a nighe, dubh ogsaid

• Inbhean:ASTM B863, AWS A5.16, ASTM F67, ASTM F136 msaa

| Ainm Coitcheann Stuth Titanium Alloys | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50 400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

♦ Cumadh Ceimigeach Titanium Wire ♦

| Ìre | Co-dhèanamh ceimigeach, cuideam sa cheud (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Eileamaidean eile Max.each | Eileamaidean eile Max.iomlan | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5-6.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Uèir Alloy TitanumFeartan corporra ♦

| Ìre | Feartan fiosaigeach | |||||

| Neart tensile Min | Neart toraidh Min (0.2%, air a chothromachadh) | Meudachadh ann an 4d Min (%) | Lùghdachadh Sgìre Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |

♦♦♦ Feartan stuthan Titanium Alloy: ♦♦♦

•Ìre 1: Titanium Pure, neart gu ìre ìosal agus sùbailteachd àrd.

•Ìre 2: An titanium fìor-ghlan as motha a chleachdar.Am measgachadh as fheàrr de neart

•Ìre 3: Titanium àrd-neart, air a chleachdadh airson plataichean Matrix ann an luchd-iomlaid teas sligean is tiùba

•Ìre 5: An alloy titanium as dèante.Neart fìor àrd.an aghaidh teas àrd.

•Ìre 9: Neart fìor àrd agus strì an aghaidh creimeadh.

•Ìre 12: Seasmhachd teas nas fheàrr na Titanium fìor-ghlan.Iarrtasan mar airson Ìre 7 agus Ìre 11.

•Ìre 23: Titanium-6Aluminum-4Vanadium airson tagradh implant lannsaireachd.