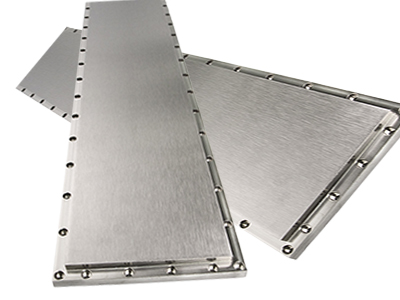

Targaid Titanium Plate

Targaid Titanium: Bidh sinn a’ cleachdadh billet alloy titanium, no truinnsear airson innealachadh a-steach do thargaidean titanium.Tha na feartan meacanaigeach agus ceimigeach aige coltach ris an fheadhainn aig stàilinn gun staoin.An coimeas ri titanium alloy, tha neart nas fheàrr aig titanium fìor-ghlan agus tha e nas fheàrr an aghaidh oxidation.Tha e nas fheàrr na stàilinn gun staoin austenitic, ach tha an aghaidh teas aige truagh.Meudachadh TA1, TA2, TA3 ann an susbaint neo-chunbhalachd, neart meacanaigeach agus cruas àrdachadh ann an òrdugh, ach tha cruas plastaig a 'lùghdachadh ann an òrdugh.

• Targaid Titanium Plate: Ìre 1, Ìre 2, Ìre 5, Ìre 5, Ìre 7, Ìre 9, Ìre 11, Ìre 12, Ìre 16, Ìre23 msaa

• Seòrsan:Targaid Cruinn, Targaid Pìoba, Targaid Plàta.ect

• Tomhas: 60/80/120(W) × 6/8/12(T) × 519/525/620(L) &60-800(W) × 6-40(T) × 600-2000(L)Gnàthaichte

•Suachdar:uachdar soilleir no uachdar picilte Acid

• Iarrtasan: air a chleachdadh ann an innealan dealachaidh semiconductor, taisbeanaidhean pannal còmhnard, filmichean electrode stòraidh, còmhdach sputtering, còmhdach uachdar workpiece, gnìomhachas còmhdach glainne, msaa.

| Titanium Alloys Material Ainm Coitcheann | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50 400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

♦ Co-dhèanamh Ceimigeach Titanium Alloys ♦

| Ìre | Co-dhèanamh ceimigeach, cuideam sa cheud (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Eileamaidean eile Max.each | Eileamaidean eile Max.iomlan | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.56.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Titanum alloyFeartan corporra ♦

| Ìre | Feartan fiosaigeach | |||||

| Neart tensile Min | Neart toraidh Min (0.2%, air a chothromachadh) | Meudachadh ann an 4d Min (%) | Lùghdachadh Sgìre Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |