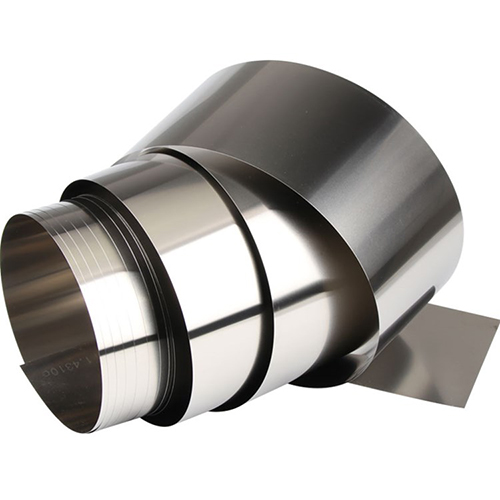

Stiall Titanium agus Foil

• Stuthan titanium agus foil:Titanium fìor-ghlan (CP) agus foil alloy Titanium,Ìre 1, Ìre 2, Ìre 5, Ìre 5, Ìre 7 agus Ìre 9

• Foirmean: stiall shingilte, ann an coil, no air spool.Seirbheis slitting ri fhaighinn

• Meud:Tighead: ≥0.01mm: 20~1000mm, Fad: Mar an t-iarrtas

• Cùmhnantan:Rolladh fuar (Y) ~ Rolair teth (R) ~ Annealed (M) ~ Inbhe cruaidh

• Inbhean:ASTM B265, AMS 4911, AMS 4902, ASTM F67, ASTM F136 etc

• Tagraidhean:Leictreonaic, ceimigean, uaireadairean, glainneachan, seudaireachd, bathar spòrs, innealan, uidheamachd plating, uidheamachd àrainneachd, goilf agus gnìomhachasan innealachaidh mionaideach.

| Titanium Alloys Material Ainm Coitcheann | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50 400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

Strip Titanium agus Foil:Bidh sinn sa mhòr-chuid a’ toirt seachad stiallan titanium fìor-ghlan de ìrean Gr1, Gr2, Gr4;Airson titanium alloy Foil, Bidh sinn sa mhòr-chuid a’ toirt seachad Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 agus ìrean eile, Tha iad air an toirt a-mach air bunait truinnsear titanium le tuilleadh roiligeadh fuar;tha pròiseas cinneasachaidh duilleag titanium nas iom-fhillte.Tha an deformation smachd nas cruaidhe ann am pròiseas rolling.That faodar a ghearradh ann an diofar mheudan a rèir feumalachdan an neach-ceannach, gu mòr a ghiorrachadh an ùine lìbhrigidh.

♦ Titanium Strip Co-dhèanamh ceimigeach ♦

| Ìre | Co-dhèanamh ceimigeach, cuideam sa cheud (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Eileamaidean eile Max.each | Eileamaidean eile Max.iomlan | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.56.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Titanum Alloy StripFeartan fiosaigeach ♦

| Ìre | Feartan fiosaigeach | |||||||

| Neart tensile Min | Neart toraidhMin (0.2%, air a chothromachadh) | Meudachadh ann an 4d Min (%) | Lùghdachadh Sgìre Min (%) | Deuchainn lùb (radius of Mandrel) | ||||

| ksi | MPa | ksi | MPa | <1.8mm Ann an tiugh | 1.8-4.8mm Ann an tiugh | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 | 4.5T | 5.0T |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 | 2.0T | 2.5T |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 | 4.5T | 5.0T |

♦ ♦ ♦ Feartan stuthan titanium alloy: ♦ ♦ ♦

•Ìre 1: Titanium Pure, neart gu ìre ìosal agus sùbailteachd àrd.

•Ìre 2: An titanium fìor-ghlan as motha a chleachdar.Am measgachadh as fheàrr de neart

•Ìre 3: Titanium àrd-neart, air a chleachdadh airson plataichean Matrix ann an luchd-iomlaid teas sligean is tiùba

•Ìre 5: An alloy titanium as dèante.Neart fìor àrd.an aghaidh teas àrd.

•Ìre 7: Superior an aghaidh corrach ann an àrainneachdan lughdachadh agus oxidizing.

•Ìre 9: Neart fìor àrd agus strì an aghaidh creimeadh.

•Ìre 12: Seasmhachd teas nas fheàrr na Titanium fìor-ghlan.Iarrtasan mar airson Ìre 7 agus Ìre 11.

•Ìre 23: Titanium-6Aluminum-4Vanadium ELI (Eadar-roinneil a bharrachd) Alloy airson tagradh implant lannsaireachd.